Introduction to Refining Waste Tire Project

products detial

Waste tire oil refining equipment

Cracking furnace:

Performance and parameters | |

Processing materials | waste tires, waste rubber, waste plastics, medical waste, urban domestic waste |

Final products | fuel oil, carbon black, steel wire, combustible gas |

Output/Model | 3 tons/day, 6 tons/day, 8 tons/day, 10 tons/day, 12 tons/day |

Reaction kettle material | Q345R/Q245R/310S++ boiler plate/stainless steel |

Thickness | 14mm/16mm/18mm |

Weight | 15 tons - 35 tons |

Power | About 15 kW/h |

Cooling type | circulating water cooling |

Required area | 450-600 square meters (width: 15 meters, length: 30-35 meters) |

Required manpower | 3-4 people |

Oil density | 0.89g/cm3 |

Combustion value | 44.30KJ/KG |

Small-sized waste tire oil refining equipment can also be customized, 100-500KG, 1 ton, etc. | |

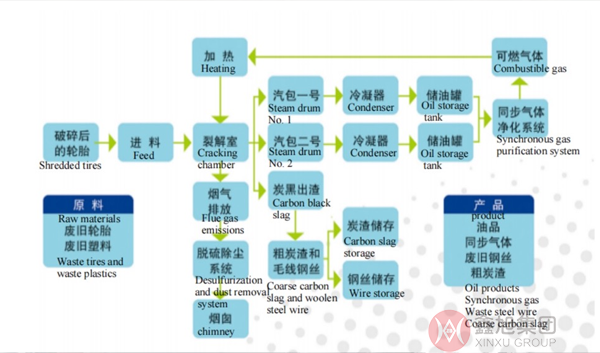

Process flow chart:

Uses of cracking products | |

Pyrolysis oil (tire refining, plastic oil) | 1) It can directly replace fuel oil for industrial or boiler heating, such as cement plants, steel plants, glass plants, etc.; 2) It can be refined into diesel for use in diesel fuel and power plants, agricultural machinery, etc.

|

Carbon Black

| 1) It can be pressed into pellets and burned for industrial heating. Its calorific value is equivalent to that of coal and can directly replace coal; 2) Toner can be refined into different standards and used as an additive for paint pigments, rubber products, etc. |

Carbon Black:

Pyrolysis Oil:

Refined oil:

Steel Wire:

Refining equipment:

Waste tires:

Cracking furnace:

Pyrolysis Oil:

Burner combustion:

Tire pre-treatment:

After the tire is shattered:

After the tire is broken and sucked on the steel wire:

Steel Wire:

Carbon Black: